Progressive Cavity Pump Parts

Various industries use a wide range of corrosive and viscous fluids to perform routine processes. Many of these fluids require special pumping equipment and systems, such as progressive cavity pumps, which help to handle viscous slurries, and their type and design vary from application to application.

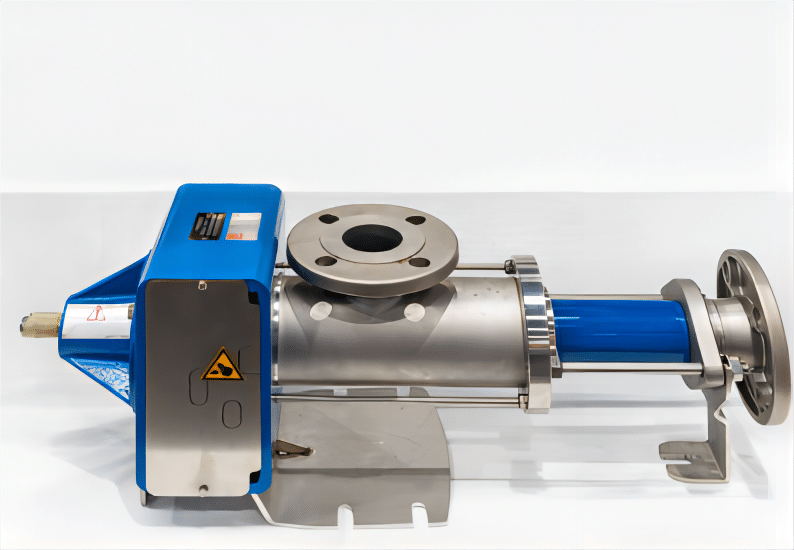

progressive cavity pump

What is a progressive cavity pump?

Progressive cavity pumps are pumps for transferring liquids and their operating principle is based on the movement of a rotating screw inside the pump chamber. Progressive cavity pumps are positive displacement pumps and their design makes them suitable for handling liquids with high viscosity, high solid particle content and containing gases.

Screw pumps are widely used in various configurations, such as vertical and horizontal types. Among horizontal pumps, progressive cavity pumps are ideal for handling highly viscous liquids, sludge, and pasty materials. Their design ensures stable flow and consistent pressure, even with challenging fluids.

Characteristics of Progressive Cavity Pumps

- Suitable for high viscosity liquids such as pastes, slurries and liquid solids.

- Capable of handling liquids containing gas, as the rotary motion of the pump chamber helps to expel the gas.

- Suitable for high temperature, high pressure, corrosive liquids and liquids containing particles.

- Operates at low speeds, reducing mechanical wear and energy consumption.

Advantages and disadvantages of progressive cavity pumps

| Advantages | Disadvantages |

| Suitable for high viscosity liquids and slurries | Relatively limited ability to handle particles and solids |

| Capable of handling liquids containing gases | High initial investment and maintenance costs |

| Good self-priming performance | Requires large installation space |

| Suitable for high temperature, high pressure, corrosive liquids | High mechanical wear and tear, requiring regular maintenance |

| Suitable for a variety of industrial fields | High operating noise level |

| Smooth operation and stable flow rate | High operator skill requirements |

| Low energy consumption | Low efficiency at low flow rates and low viscosities |

Working Principle of Progressive Cavity Pumps

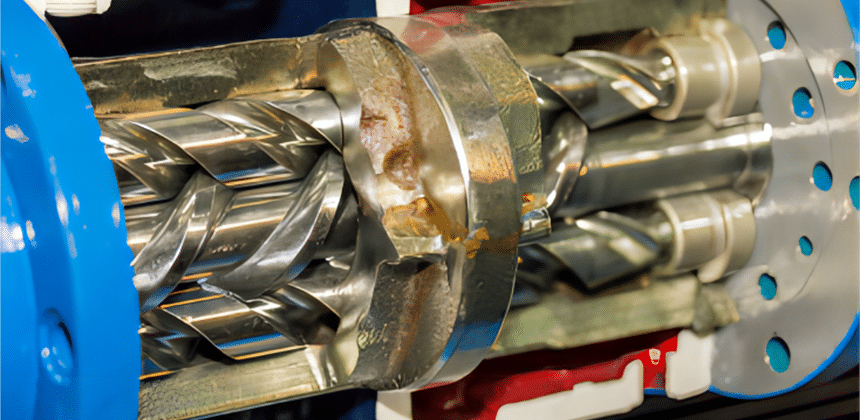

Rotor and Stator Structure

- The rotor is a single-helix metallic screw (typically stainless steel) with a precise shape.

- The stator is a double-helix, flexible sleeve (usually made from elastomer) that matches the rotor’s geometry.

- Together, they create a series of sealed cavities that move from the suction side to the discharge side.

Rotation and Cavity Formation

- As the rotor turns inside the stator, cavities are progressively formed, filled with fluid at the suction side.

- These cavities trap a fixed volume of fluid.

Progressive Movement of Fluid

- The cavities shift forward with each rotation, carrying the fluid with minimal mixing or shear.

- This ensures steady, laminar flow without pulsation or turbulence.

Fluid Discharge

- At the discharge side, the fluid exits at a consistent pressure and volume, largely independent of discharge pressure (up to pump limits).

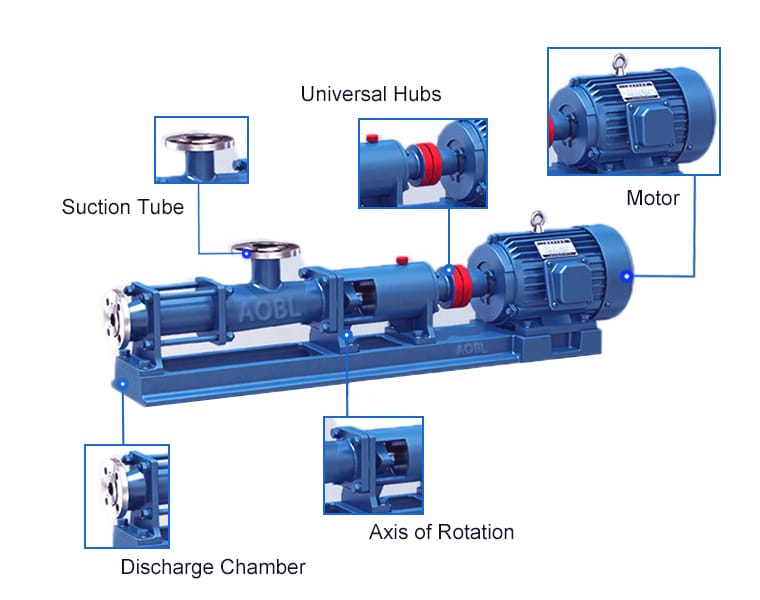

Components of a progressive cavity pump

- Screw: The screw is the core component of a screw pump and usually consists of a spiral shaped vane. The rotation of the screw conveys the liquid from the inlet to the outlet.

- Rotor and stator: The screw in a screw pump works in conjunction with the rotor (the part that drives the screw) and the stator (the part that is fixed inside the pump casing) to create a spiral motion in which the liquid is propelled.

- Pump casing: The pump casing is the external housing that houses the screw, rotor and stator, and is usually designed and made of materials that are adaptable to the characteristics of the liquid that the pump is intended to handle.

- Seals: Screw pumps usually require seals between the rotating parts and the pump casing to prevent leakage.

- Drive: Screw pumps require an external drive, such as an electric motor or hydraulic system, to move the screw and rotor.

- Accessories and fittings: Depending on the application requirements, screw pumps may come with accessories and fittings, such as feed hoppers, air filter regulator lubricator, temperature sensors etc.

- Flanges: The inlet and outlet flanges of screw pumps play a key role in pump performance, stability and operation. They not only connect the pump to the piping system, but also affect the flow, pressure and efficiency of the pump. Correct selection and installation of inlet and outlet flanges can ensure the normal operation of the screw pump, improve efficiency, reduce the risk of leakage and damage, while facilitating maintenance and repair.

- Pump head: Is the head pressure, also known as head. Pump head is the height to which the pump can pump the liquid, usually expressed in meters (m). Screw pumps work by rotating the screw to push the liquid to produce a certain pressure, so that the liquid can overcome gravity and pipe resistance, so as to lift to a certain height. This height is the pump head, which represents the difference in height of the liquid that the screw pump can overcome.

- Pump couplings: Pump couplings are typically used to connect a progressive cavity pump to a drive such as a motor or engine. Pump couplings help transfer rotational power and ensure stable pump operation. This helps to minimize vibration and shock, thereby extending the life of the progressive cavity pump and improving performance.

Difference between progressive cavity pumps and diaphragm pumps

| Features | Diaphragm Pumps | Progressive Cavity Pumps |

| Working Principle | Which draw in and discharge fluid through the reciprocating motion of a diaphragm | Positive displacement pump that pushes fluid through a rotating screw to the outlet |

| Fluid Conveying Method | Pulsating fluid transfer with intermittent flow | Continuous fluid transfer with steady flow |

| Self-Priming Capacity | Good self-priming ability | Requires auxiliary equipment to support self-priming |

| Seal Structure | Diaphragm isolates liquid from gas contact, less leakage | Less leakage, suitable for high pressure or high temperature environment |

| Usage Scenarios | Suitable for corrosive liquids, volatile liquids and so on | Handles specialized fluids such as high viscosity, high temperature, and high pressure |

| Maintenance cost | Diaphragm and valve body are easy to replace, low maintenance cost | Faster wear and tear of parts, higher maintenance cost |

| Applicable industries | Chemical industry, environmental protection, food, water treatment and other fields | Chemical, petrochemical, food, pharmaceutical and other fields |

Diaphragm pumps and progressive cavity pumps have their own advantages in different application scenarios, and choosing the right type of pump depends on the specific process requirements and fluid characteristics.

What material is chosen for the rotor of a progressive cavity pump?

Rotor materials for progressive cavity pumps are typically selected based on the nature of the liquid being pumped, temperature, pressure, and specific application requirements.

- Stainless steel: Stainless steel is typically used for pumping less corrosive liquids and has excellent corrosion resistance and strength. Stainless steel can be used in a variety of industrial applications.

- Carbon steel: Carbon steel is usually used in general industrial applications, has good wear resistance and mechanical strength, but in corrosive liquids may need to be protected.

- High-chromium cast iron: This material has excellent abrasion resistance and is suitable for handling liquids containing particles or abrasive substances.

- Polymer materials: Some progressive cavity pumps use polymer materials, such as polypropylene (PP) or polytetrafluoroethylene (PTFE), to handle liquids with more specific chemical properties, with good corrosion resistance and chemical stability.

- Other special alloys: For some extreme operating environments, such as high temperature, high pressure or extremely corrosive liquids, special alloys may be required, such as Hastelloy, nickel-based alloys, and so on.

Screw pump application industry

Papermaking

- Transferring pulp to dosing/metering systems

- Transfer of dyes, fillers and fixatives to dosing systems

- Transfer of wastewater from the forming stage (pressing, filtration, bleaching and coating) to purification/treatment systems

Wastewater Treatment

- Transfer or thickening of sludge from tanks to dewatering systems

- Transfer of treated sludge to storage silos, tanks or drums

- Dosing and metering of polymers and additives

- Filter press feed

Biogas / Anaerobic Digestion Industry

- Pumping liquid livestock to collection tanks or pumping animal waste directly to digesters

- Liquid fertilizer is injected from the liquid effluent collection tank into the digestate feed pumps

- Transfer of digestate from biomass collection tanks to digesters

- Pumping of partially fermented biomass from the main digester to the post-digester

- Transfer of digestate from the post-digester to final storage and treatment

Screw pump failure maintenance

- Troubleshooting

- Cleaning Maintenance

- Lubrication and seal check

- Replacement of spare parts

- Tightening connections

When a progressive cavity pump fails, it needs to be diagnosed and troubleshooted before maintenance. Regular preventive maintenance is essential to extend the life of the progressive cavity pump and keep it running properly.

Can PCP pumps be used for dosing?

Progressive Cavity Pump can be used for dosing applications. PCP pumps are positive displacement pumps that work on a principle based on a helical action between the screw and the casing, enabling stable delivery of a wide range of liquids, including chemicals, additives, and chemicals. PCP pumps are able to control the flow rate accurately during the dosing process, enabling precise dosing of chemicals, e.g. in wastewater treatment, industrial processes, food processing, pharmaceutical production, etc.

Eccentric screw pumps

- Principle of operation: Eccentric screw pumps convey liquids from the suction end to the discharge end of the pump through the movement between a screw and a profile-matched elastic sleeve.

- Advantages: Suitable for conveying liquids with high viscosity and large solid particles, high stability, suitable for dosing viscous liquids.

- Disadvantages: Possible risk of leakage, requires stricter sealing measures.

Progressive Cavity Metering Pump

- Principle of operation: Progressive cavity metering pumps are also a type of screw pump, but are specifically designed to accurately meter liquids, usually with higher flow control accuracy.

- Advantages: Suitable for dosing applications where precise metering is required, with higher flow control accuracy.

- Disadvantages: May require more maintenance and cleaning when handling highly viscous liquids and particulate matter.

Summary

These components work together to enable screw pumps to efficiently and consistently transfer liquids for a wide range of industrial sectors and application scenarios. AOBL is a fluid transfer specialist, we also offer air operated diaphragm pumps, electric diaphragm pumps, sanitary diaphragm pump, and pump spares, contact our dedicated team of technical specialists for a solution to your problem.