Plastic Viscosity

What is plastic viscosity?

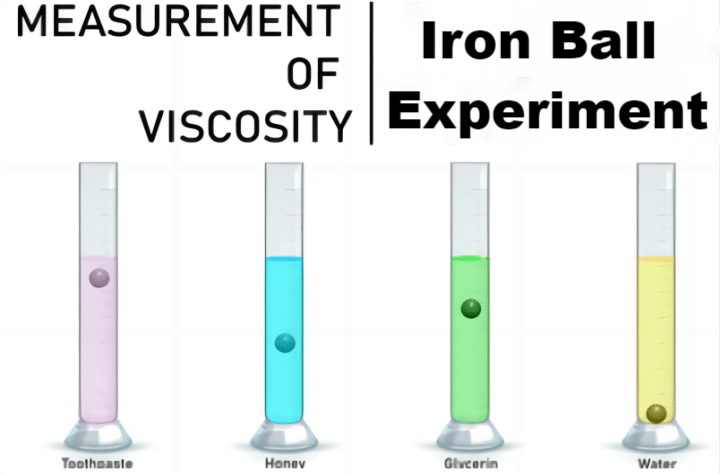

Plastic viscosity is a non-Newtonian property of a fluid and refers to the fact that a fluid does not flow until a shear force is applied. Unlike Newtonian fluids, plastic fluids do not begin to flow until enough shear is applied. Plastic viscosity is often used to describe very thick substances like slurries, paints, etc., which are able to retain their shape after the application of force is stopped.

Plastic viscosity is one of the important parameters of Bingham’s plasticity model, the other being the yield stress (PV), where the drilling fluid initially resists flow until the shear stress exceeds a certain limit, which breaks the inter-particle bonds present in the fluid. Once the fluid begins to flow, the shear stress and shear rate are linearly related. And plastic viscosity is a measure of the fluid’s resistance to flow.

Two main parameters of plastic viscosity

- Yield point: The maximum shear force at which a plastic fluid can retain its shape without flowing until sufficient shear is applied. Once the yield value is exceeded, the fluid begins to become plastic, i.e., it begins to flow.

- Plastic viscosity: Describes the viscosity exhibited by a fluid as it flows after the yield value. Plastic viscosity is often used as a measure of fluid viscosity, i.e., the amount of shear required for the fluid to flow when the yield value has been exceeded.

The understanding of plastic viscosity is important for handling thick fluids, paints, slurries, etc. in industrial and chemical applications.

Plastic Viscosity In pumping fluids, plastic viscosity affects the flow properties of the fluid and has a significant impact on pump selection and performance.

Control Of Plastic Viscosity

- Temperature control: In general, increasing temperature decreases the viscosity of a plastic fluid, making it easier to flow. Conversely, lowering the temperature increases the viscosity. By controlling the temperature of a fluid, its plastic viscosity can be adjusted to suit different process requirements.

- Adding diluents: Adding appropriate diluents or solvents to a plastic fluid reduces its consistency and thus reduces the plastic viscosity.

- Adding flow aids: The flow of plastic fluids can be improved by using specially designed flow aids. These additives reduce the cohesion of the fluid, making it easier to flow.

- Mechanical shear: The application of shear by mechanical means, such as the use of agitators or mixing equipment, can disrupt the structure of a fluid and thereby reduce its plastic viscosity. This method is often used to treat high viscosity fluid and liquid.

- Selection of suitable additives: The use of several specially designed additives, such as modifiers and rheologists, can change the rheological properties of a fluid, thereby adjusting its plastic viscosity.

Difference Between Viscosity And Plastic Viscosity

| Characteristics | Viscosity | Plastic Viscosity |

| Define | Describes the degree of viscosity and resistance of a fluid. | Describes the resistance to flow of fluids that begin to flow only at the onset of shear stress. |

| Fluid type | Applies to all fluids (liquids and gases). | Applies mainly to liquids. |

| Unit of Measurement | Usually measured in units of dynamic or kinematic viscosity. | No specific units, usually expressed in terms of plastic flow indices. |

| Flow behavior | Describes the overall flow properties of a fluid. | Focuses on the behavior of the fluid at the onset of shear stress. |

| Influencing factors | Affected by many factors such as temperature and pressure. | Depends on the type and nature of the fluid and the externally applied stresses. |

Influence Of Plastic Viscosity

Plastic viscosity has a significant impact on liquid transfer and pump efficiency.

- Pump efficiency: Highly plastic viscous fluids require more force to overcome the initial resistance, which may result in more energy being required to start the pump. This may affect pump efficiency, especially when handling highly plastic fluids.

- Power requirements: An increase in the plastic viscosity of a fluid usually results in the pump requiring more power to transfer it. High plastic viscosity means that more force is required to overcome viscous resistance when transferring the fluid, which may require a more powerful pump or more power.

In liquid transfer systems, understanding and controlling plastic viscosity is critical to ensuring efficient and reliable operation. This may involve measures such as adjusting operating conditions, selecting the proper type of pump, and using heating or mixing equipment to reduce the viscosity of the liquid. When it comes to liquids with high plastic viscosity, it is important to design and select the proper pump system to maximize efficiency and minimize energy consumption.

Pumps For Plastic Viscosity

The selection of an appropriate pump is directly related to the plastic viscosity of the liquid, as different types of pumps exhibit different results when handling liquids of different viscosities.

Centrifugal pumps: Centrifugal pumps are typically suitable for liquids with low to medium viscosity. When handling liquids with low plastic viscosity, vertical multistage centrifugal pumps are the best choice for low flow and high head pumping needs. However, when handling high viscosity liquids, centrifugal pumps can be challenging to start and run.

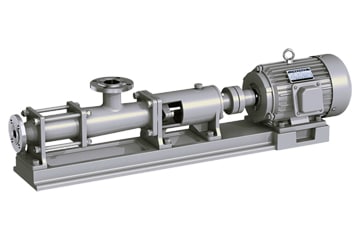

Progressive cavity pump: For liquids with high plastic viscosity, progressive cavity pump may be a more appropriate choice. Eccentric screw pumps can effectively handle high viscosity and viscous liquids because they are designed to provide greater torque and more consistent fluid delivery.

Diaphragm pumps: Diaphragm pumps are usually suitable for medium viscosity fluids, but their design allows them to handle some high viscosity fluids as well. AOBL 1/2″ Classic double diaphragm pumps offer powerful performance in a small package

Piston pumps: Piston pumps are suitable for applications requiring high pressures, and they are also well adapted for some high viscosity liquids.

When selecting the appropriate pump, it is important to consider not only the plastic viscosity of the liquid, but also the other properties of the liquid, the required flow rate, pressure requirements, and the specific application scenario.

Conveying System Design Elements for Plastic Viscosity

- Conveying system: In the design of the system, it is necessary to ensure that the pipe size is large enough to accommodate the flow of high plastic viscosity liquids and to minimize fluid friction losses.

- Pump packages: Different types of pumps exhibit different effects on liquids with different viscosities. Need to ensure that the selected pump can effectively handle a specific viscosity range of liquids. In addition, related equipment such as valves, piping and connectors also need to be selected according to the plastic viscosity of the liquid to ensure the coordinated operation of the entire system.

- Temperature control: Plastic viscosity typically varies with temperature. In the design of the system, it is necessary to consider the temperature variations that may be encountered by the fluid during transportation and take measures accordingly to control the temperature in order to maintain the desired plastic viscosity range.

- Flow and Pressure Requirements: High plastic viscosities may require more powerful pumping systems to produce adequate flow and pressure.

- Maintenance and Cleaning: Plastic viscous fluids may be more likely to deposit or adhere in the system, so maintenance and cleaning of the pump system needs to be considered.

Summary

Plastic viscosity is a rheological property unique to liquids and has a significant impact on the behavior of liquids in a variety of engineering applications. Consideration of plastic viscosity in liquid transfer, pump selection and system design is a key factor in ensuring efficient system operation.

The AOBL team of professionals are experts in air operated diaphragm pumps and other fluid transfer pumps, offering electric diaphragm pumps, filter press feed pumps, chemical pumps and pump accessories. We meet the most challenging and demanding pumping tasks you face with superior pumping technology and engineering innovation. Feel free to contact our team of professional engineers for an equipment quote or consulting solution.